The subject guitar is a Santa Cruz Model D, which retails for about US$2,800 or S$4,700.

When the guitar was first brought to my attention, the guitar has already been worked on by 2 other individuals/shops. The neck had about a .040" relief and the top was bellying up due to string tension and the local high humidity. In order to improve the instrument's playability, the 1st shop dressed the fret ends and "tried" adjusting the truss rod but I understand that didn't help improve the action.

The 2nd shop, which a lot of people hold a high regard for here in Singapore, "cooked" the guitar in an attempt to de-humidify the instrument. Please see the results of the ill thought out "experiment". I suspect the top of the guitar was subjected to some outboard heating device that bubbled the nitro-cellulose lacquer and left an unsightly patch just below the bridge.

The finish on the top and sides are ruined!!! There're bubbling on the top, the nitro-cellulose lacquer has "melted" around the bridge. The finish on both sides have also bubbled and developed a “haze” within the finish. A discolored patch has formed on the lower left area below the bridge and the worst damage of all is the center seam of the book-matched top has separated below the bridge to the location of the top transverse brace!!!

After de-humidifying the guitar, I made a spruce cleat and fitted it where the seam separated. The truss rod was also adjusted and saddle lightly sanded. When tuned to E flat with D’Addario custom light gauge, there’s a relief of .003” The now comfortable action measures .110” on the bass side and .903” on the treble side at the 12th fret.

All the guitar needed was just a truss rod tweak and correct set up by a knowledgeable repairman or luthier. There’re a couple of local “guitar butcher” who advocate “heat treatment” and they never work and always do more harm and damage than fix the problem. Be warned!!!

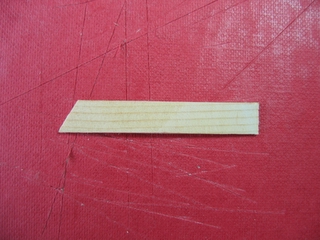

Close up of seam separation and rough Spruce cleat.

The Spruce cleat’s being glued in place. These rare earth magnets are very powerful and they make a good repair clamp for those hard to reach places.

The cleat’s glued on, the top separated area is reinforced and the guitar’s strung up and ready to go.

Here’re 2 Santa Cruz D models for comparison. For those who can’t tell, the guitar on the left is the one that needed work. Notice the top discoloration and hazy sides.